- City Fajr Shuruq Duhr Asr Magrib Isha

- Dubai 04:20 05:42 12:28 15:53 19:08 20:30

3D printing has not yet got into the mainstream but we already have new advanced 4D printing technology that can revolutionise the way things to be printed in the future.

Imagine a day when you can build structures using mushrooms, a complete aircraft cabins with self-adjusting seats and space that can change according to the users’ requirement, a car that can self-assemble itself, a Nano robot that can get into your body and release just the required amount of payload of medication necessary to heal.

Work is on to create the new 4D printing technology, more advanced and scientific that it can self-assemble different parts and create a complete solution.

The technology is still under study at primary stages of testing, mainly at the Massachusetts Institute of Technology (MIT) and led by researcher Skylar Tibbits and Carlos Olguin, Head of Bio Nano Programmable Matter Group at Autodesk.

Tibbits is working on bio molecular self-assembly and human scale 4D printing and printing multi-materials that can change its shape over time.

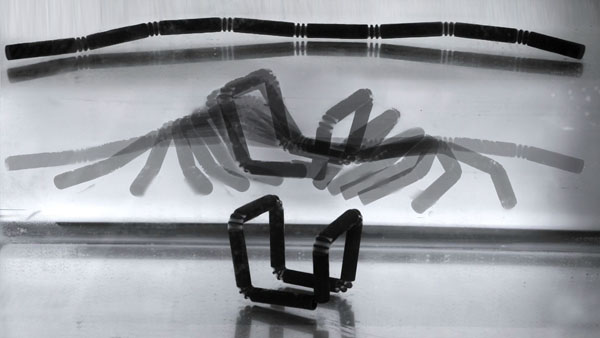

As part of his Project Cyborg Tibbits used to simulate various shape transformations and optimise folding sequences in 4D Printing, the video below is a demonstration of Tibbits research at the TED conference in 2013.

According to him the phenomenon of self-assembly is scale-independent and can be utilised for self-constructing and manufacturing systems at nearly every scale.

“Self-assembly promises to enable breakthroughs across every application of biology, material science, software, robotics, manufacturing, transportation, infrastructure, construction, the arts, and even space exploration,” says his note explaining the possibilities.

A team of engineers at Harvard and MIT have designed and built a flat-packed robot that assembles itself and walks away.

Olguin on the other hand has been researching the intersection of bio/nano/programmable matter and the design spaces currently supported by Autodesk software such as manufacturing and the building industry.

The idea at Autodesk is to move away from concrete to bio/nano/programmable matter such as synthetic biology.

Carl Bass, President and CEO of Autodesk, says he is quite excited about the new developments which according to him could define the future of how things are made.

“Bio molecular self-assembling units will soon be a reality and the idea of 4D printing or whatever name various people prefer to call it is all about self-assembly. One good example is the things built out of DNA,” he says.

Shawn Douglas and his associates at the University of California, San Francisco, are working on a nano robot built using DNA strands that can be used to treat cancerous patients.

The robot opens up only when it comes in contact with cancerous shells and opens up and releases medication to treat these specific cancerous cells.

“This when it finally becomes a reality will be a significant enhancement of how we treat cancer from what is being done today. In a few years, several of current day practices will look barbaric,” he says.

![]() Follow Emirates 24|7 on Google News.

Follow Emirates 24|7 on Google News.