- City Fajr Shuruq Duhr Asr Magrib Isha

- Dubai 04:20 05:42 12:28 15:53 19:08 20:30

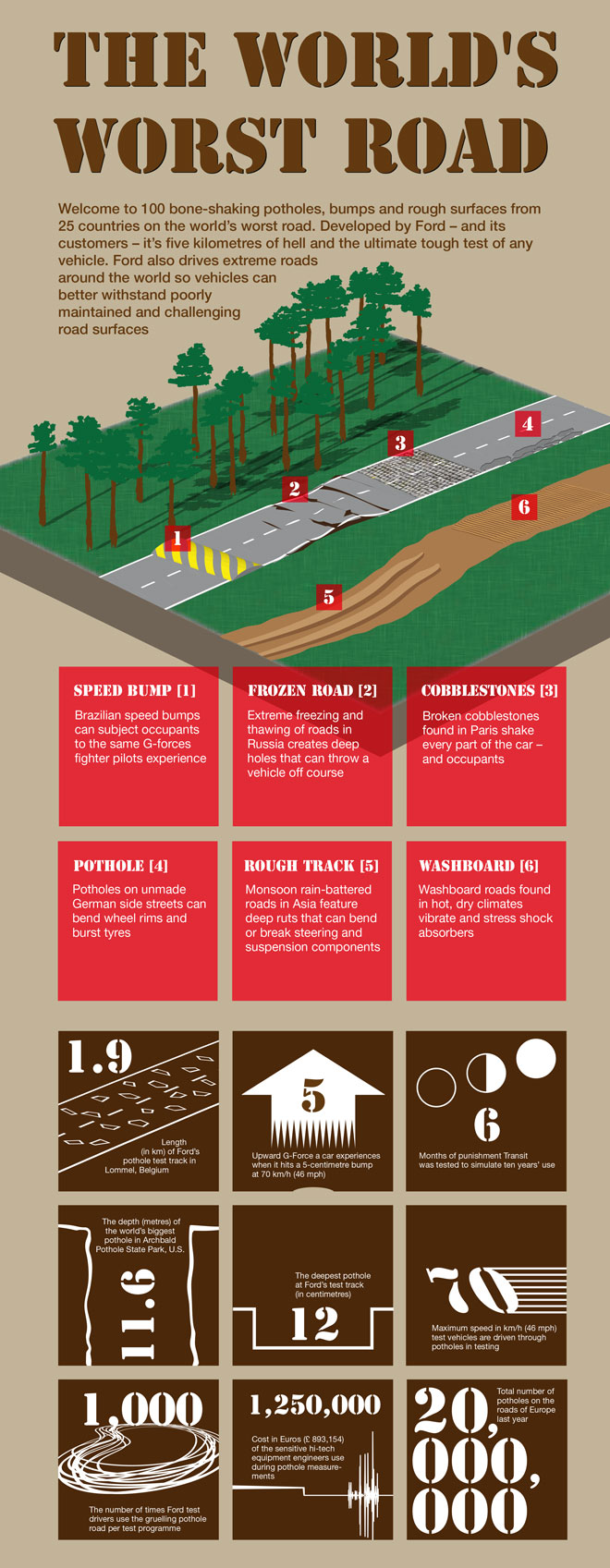

Ford Motor Company has created a diabolical 1.9-kilometre (1.2 mile) road that consists of precise replicas of some of the worst potholes and road hazards from around the world.

What’s the point of this boulevard of broken suspensions?

To help engineers create more robust chassis systems and develop new innovations to ensure its vehicles can better withstand the world’s increasingly choppy roads.

“From a rutted traffic junction in China to a bumpy German side-street, this road is a rogues’ gallery of the most bruising surfaces that our customers might encounter,” said Eric-Jan Scharlee, durability technical specialist, at Ford’s Lommel Proving Ground, in Belgium.

“By incorporating these real-world challenges into our test facilities we can develop future vehicles to better cope with challenging conditions.”

Potholes and other rough road surfaces have become a pricey problem for motorists around the world.

Last year in the UK alone, the Royal Automobile Club responded to more than 25,000 pothole-related breakdowns – a nearly 25 per cent increase just since 2014.

Poor condition and lack of maintenance of European roads are said to contribute to at least one third of all accidents every year.

The road that Ford has created is part of 80km (50 miles) of test tracks at the carmaker’s test facility in Lommel, Belgium.

It incorporates potholes from Europe and the US, and simulates more than 100 hazards from 25 countries worldwide. In the past three years alone, Ford engineers’ search for scary road hazards has taken them to Austria, France, Germany, Italy, Russia, Spain, Switzerland, and the UK, as well as Asia, Australia, North America, and South America.

Engineers are always investigating potential new additions for inclusion at the facility. Employing similar equipment to that used by seismologists studying earthquakes, the engineers drive through the potholes at speeds of up to 70 km/h (46 mph), using sensors to record the loads and strains to the suspension and components. This includes surfaces as diverse as granite blocks from Belgium, cobbles from Paris, and speed bumps from Brazil.

Ford claims its obsession with making sure its cars can withstand the world’s worst roads has led to innovation.

As an example, it flaunts its debut of Continuous Control Damping with Pothole Mitigation technology in Europe on Mondeo, Galaxy and S-Max. The technology adjusts the suspension if it detects that a wheel has dropped into a pothole, and can help protect the suspension from damage.

Ford says its Tyre Pressure Monitoring System alerts drivers to punctures, and Electronic Stability Control can help drivers maintain control of their vehicle when avoiding obstacles.

It adds that all its vehicles for Europe are tested at Lommel, where its engineers and test drivers cover more than 6 million kilometres (3.7 million miles) every year.

Test drivers there drove the all-new Transit over the course more than 5,000 times as part of a testing regime designed to simulate ten years’ punishment in just six months, it notes.

Test facilities also include a high-speed circuit, salt- and mud-baths and corrosion testing in high-humidity chambers. Prototype vehicles also are driven worldwide in temperatures ranging from -40 C to 40 C.

“Analysing data inputs during vehicle testing has enabled Ford to develop a range of advanced driver aids and design modifications to help continually improve the safety and robustness of our vehicles,” Scharlee said.

![]() Follow Emirates 24|7 on Google News.

Follow Emirates 24|7 on Google News.